Cooling Towers

Cooling tower can be identified based on four main parameters: water inlet temperature to the cooling tower, water outlet temperature from the cooling tower, maximum wet bulb temperature of the installation environment and circulating water flow. Using the cooling tower selection diagram or by entering these four parameters in the cooling tower software, the tonnage of the cooling tower can be determined and the capacity of the required cooling tower can be determined. After determining the tonnage and capacity, the current water flow and cooling tower connections must be ensured.

The temperature of water entering and leaving the cooling tower (which is usually ordered by the user) is another important design parameter of the cooling tower. In fact, the choice of these temperatures affects the heat load of the cooling tower. The difference between the inlet and outlet water temperatures is called “Range” and the difference between the outlet temperature of the cooling tower and the humid air temperature is called “Approach”, the amount of Approach in the lowest case can be 3 degrees Celsius. This means that the cooling tower can cool water up to 3 degrees above wet bulb temperature. by increasing the “Range” or decreasing the “Approach”,the heat load of cooling tower will increase. Therefore, the inlet and outlet temperatures of the cooling tower affect the heat load and the design of the cooling tower.

Circulating water flow in the cooling tower: Another parameter that affects the design of the cooling tower is the inlet water flow (this parameter is also announced by the user). Water flow is actually the amount of water per unit time that must be reached from a temperature to a lower temperature. Circulating water flow is proportional to the connections of the cooling tower device, usually the water flow inside the connections is designed to fit at a speed of 2.5 meters per second.

Open circuit cooling towers – COUNTER FLOW

SFC Fiberglass Cooling Tower

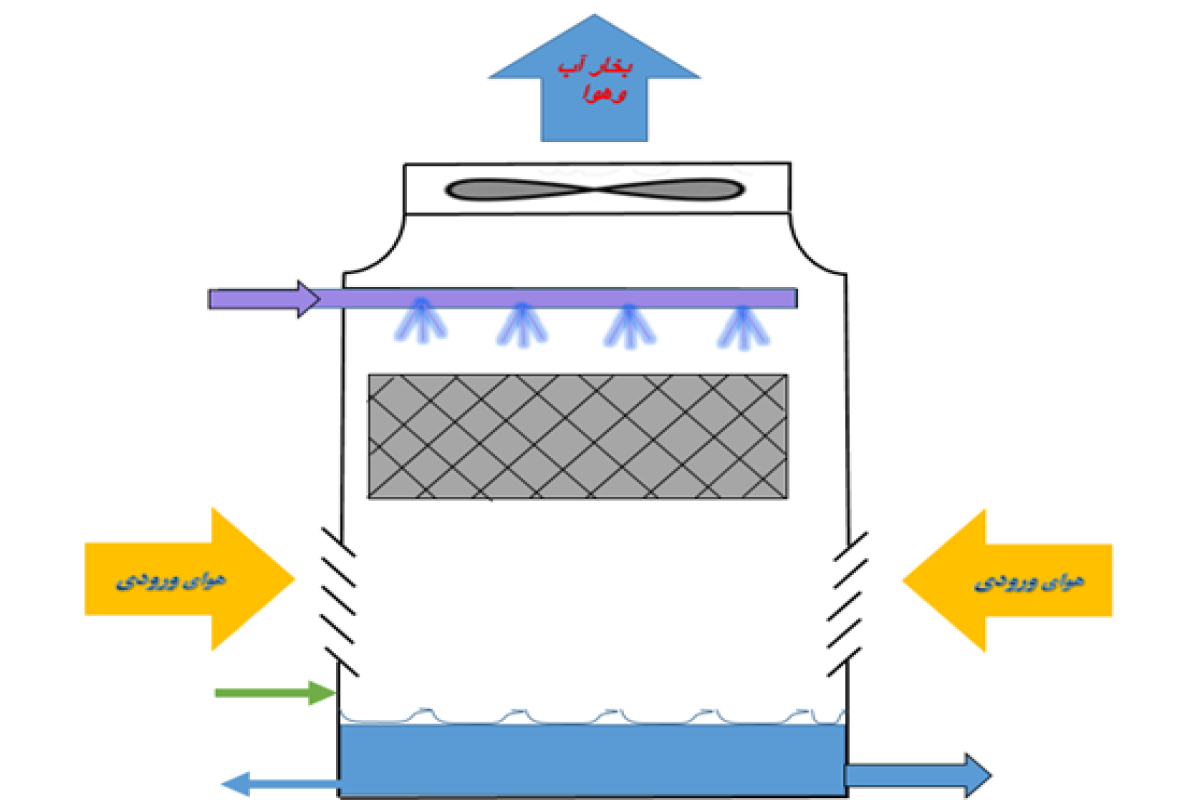

These cooling towers are counter flow type. Hot water Cascading down on PVC or PP fill packs by anti clogging nozzles and water particles are in contact with the air flow moving from the bottom of the device, heat energy transfer and mass transfer occur simultaneously. Evaporation of part of the circulating water due to the latent heat of the water will cause double cooling of the remaining water. The SFC cooling tower will minimize water loss due to the use of a drift eliminator at the highest air outlet. The body of this model is made of FRP which has a less weight than metal models.

Open circuit cooling towers – COUNTER FLOW

Cubic Galvanized Metal Cooling Towers SMC

These cooling towers are similar to SFC cooling towers in dimensions and thermodynamic performance and they are considered as counter flow cooling towers. The structure is made of galvanized metal with appropriate thicknesses. The water is sprayed on film or splash type of filling made of P.P or P.V.C. these cooling towers have a fiberglass axial fan and their installation at the project site is very fast and easy. Also, the water distribution system is anti-sediment and has a low maintenance cost.

Open circuit cooling towers – COUNTER FLOW

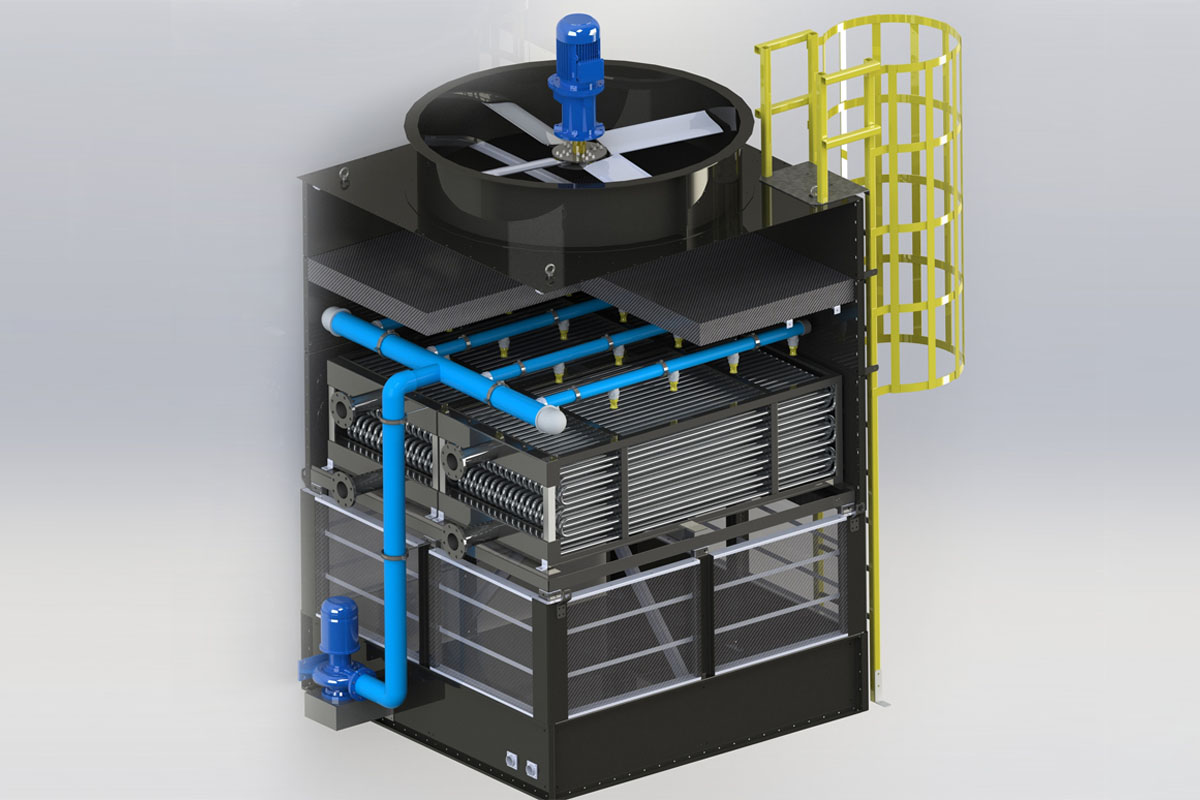

Hybrid Closed Circuit Cooling Towers

In this type of cooling tower, the cooling water of the system circulates in a closed circuit consisting of one or two coils that are designed according to the environmental conditions and the amount of heat load of the system, therefore in terms of suspended particles and any dust in the environment will be completely isolated..

The water inside the coil pipes will decrease in temperature in the vicinity of the tower open circuit water and cool air flow.

Therefore, due to the closed circuit, if the system water is charged with soft water, it has no additional particles forever and is suitable for sensitive systems such as cold water condensers and exchanger.

Also, due to the need for less water flow in the internal cycle, or the presence of cool air in the middle seasons, the amount of makeup water, which is used in the cooling tower cycle will be reduced.

The design and analysis of the type and size of the coil pipes used in the cooling tower, is done by the relevant software by considering the environmental conditions of each project, the amount of water flow and the desired inlet and outlet temperature.

Open circuit cooling towers – COUNTER FLOW

Cubic Galvanized Metal (Centrifugal Fan) Cooling Towers SCMC

These cooling towers are counter flow type, hot water is distributed through cooling nozzles and water distribution system on the cooling surfaces and air flows from the bottom to the top by centrifugal fans on the cooling surfaces and evaporates a small part of Water evaporates, this evaporation causes the remaining water to cool, which is collected in the basin of the device.

Open circuit cooling towers – CROSS FLOW

Cubic Cross Flow Cooling Towers SXC

These are cross-flow cooling towers used in residential, office and industrial buildings. Water is sprayed by gravity and without the use of nozzles. The Fill pack and Drif eliminator used in this type of cooling tower are of the special types for cross-flow cooling towers, so that these components are located completely in front of the air inlet louvers, located on the sides of the device, the air flow after entering, changes its direction by 90 degrees and is transferred to the top of tower or the air outlet. The structure of this type of cooling towers is made of HDGS profiles and its body is made of fiberglass. One of the advantages of this model is easy access to the interior space and its service and maintenance. Although the refrigeration capacity in selecting the tower depends on the geography of the region, ie the temperature of the wet bulb and the altitude above sea level in the same region, but in the table below the dimensional characteristics of different models and the approximate capacity of this type of cooling towers, are inserted.

Open circuit cooling towers – CROSS FLOW

Cubic Metallic Cooling Towers SC

These cooling towers are made of cross-flow type encountering water and air. Their axial fan is mounted on the wall of the cooling tower at the air outlet and is controlled by a belt from an electric motor mounted on the roof of the cooling tower. To convert water into fine particles, wood mesh (processed pine wood) is used perpendicular to each other. In this type of cooling tower, the incoming water enters the basin that are installed on the roof and is sprayed by gravity on the internal wooden filling. The body of this type of cooling tower is made of galvanized steel with suitable thicknesses and has excellent strength and longevity.

Open circuit cooling towers – CROSS FLOW

Trapezius Cooling Towers STC

These cooling towers are cross-flow type withencountering water and air. And are structurally quite similar to the SC towers but in higher capacities. The method of selecting this type of cooling tower, like the SC model.

Cooling Towers

Concrete cooling towers

When the water flow rate is high, the cooling range is high, or there are needs other than conventional cooling towers, industrial cooling towers are used instead of common cooling towers. Industrial cooling towers are often two types of towers with concrete body or metal or concrete structure with fiberglass cover. It is worth mentioning that the use of towers with concrete body is much more common.

As it is clear from the name of these towers, its body and structure are made of concrete.

The concrete cooling tower has the longest lifespan compared with other cooling towers. And this makes the concrete towers with the lowest amount of repair factor.

Concrete cooling towers play a very important role in the process of cooling systems in power plants, refineries and other industrial units.

Saphyad Industrial Company with more than 50 years of experience in the field of cooling and heating facilities and the first cooling tower manufacturer in Iran, relying on the knowledge and experience gained during these years, has designed, built and supplied many cooling towers in Metal, oil, gas, petrochemical and chemical industries.

Also, in addition to the mentioned capabilities, this company is ready to cooperate in the field of designing and supplying cooling tower equipment, including filtration packages and chemical injection packages.