Chiller device

chiller is a heat exchanger that provides cold water in the air conditioner coil or fan coil. Chillers are divided into two categories, evaporative and absorption compression, in terms of refrigeration system.

Chiller device

Evaporative condensing chillers

These chillers are basically composed of evaporator, compressor, condenser, expansion valve and a number of control devices. Nahan takes its evaporation from the running water in the pipes and cools it. The dry refrigerant vapor goes to the compressor through the suction pipe and its pressure and temperature are increased and sent to the condenser. Inside the condenser, the hot refrigerant vapor is heated by the running water. It is gradually distilled in the pipes, after passing through the expansion valve and reducing the pressure, it is sent to the evaporator pipes again to repeat the above process. The cold water prepared in the chiller is sent to the coil of the air conditioner or fan coil by the pump.

Chiller device

Absorption chillers

The components of these chillers include evaporator, absorber, condenser generator, heat exchanger, pump and other auxiliary devices. The refrigerant vapor produced in the evaporator is absorbed by the absorbent liquid (lithium bromide) and makes a dilute solution. This solution sent by the pump to the heat exchanger, its temperature increases, and then the temperature rises again until the refrigerant liquid in the evaporated solution is separated from the solution. In this way, by separating a large amount of refrigerant liquid, the concentrated solution It returns to the absorber through the heat exchanger. The refrigerant vapor produced in the generator goes to the condenser, where it is distilled and goes to the evaporator. Inside the evaporator, the refrigerant liquid loses its latent heat of evaporation from the running water. It takes the pipes and cools it. The successful process is repeated with the refrigerant vapor absorbed by the lithium bromide. In order to increase the efficiency of the heat exchanger, lithium bromide liquid and refrigerant are sprayed on the pipes in the absorber and evaporator, respectively.

Chiller device

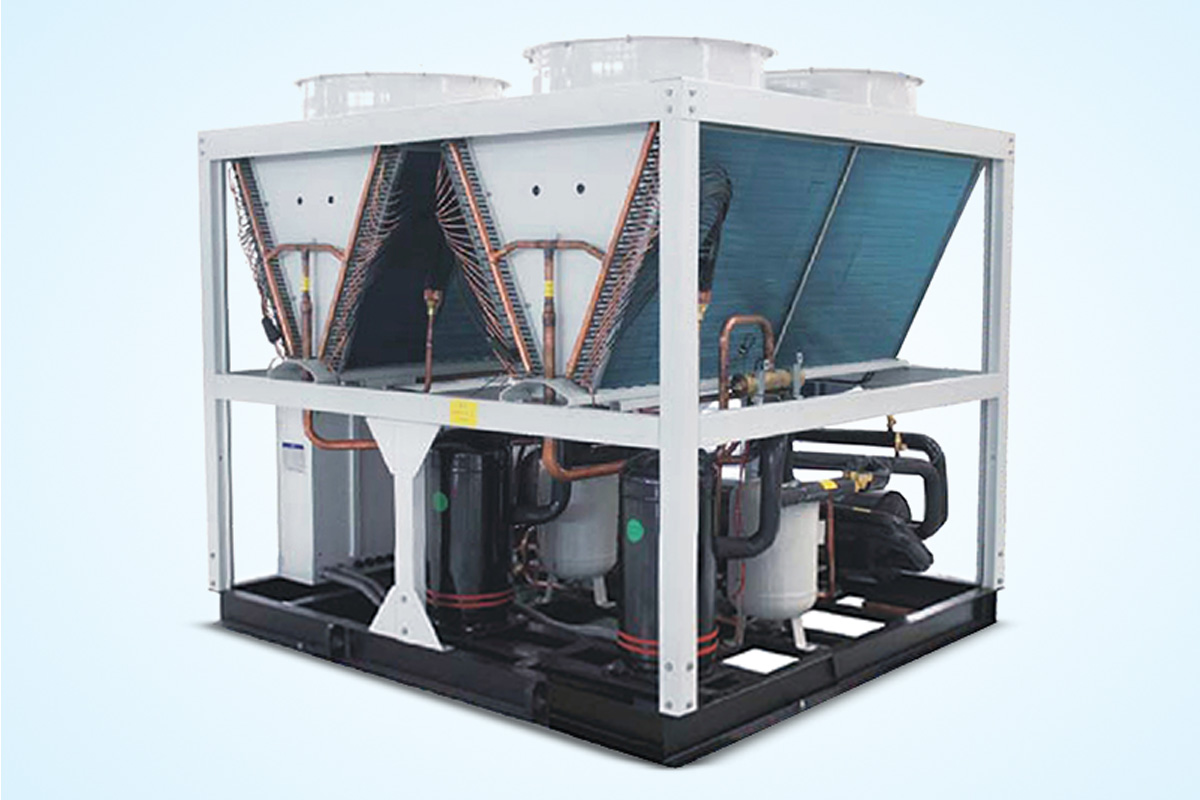

Screw air-cooled compression chillers

These chillers are designed and produced from the capacity of 40 tons of cooling to 350 tons of cooling with R22 gas and from the capacity of 6 tons of cooling to 350 tons of cooling with R134a gas, and in other capacities can also be designed according to the order in special uses. and production. Screw air chillers have reliable working, very long life span and simple maintenance conditions, can be used in different climate zones, and their most important feature is not depending on water consumption. In the new and advanced generation of air chillers, the device is designed and produced in adiabatic conditions, which reduces the consumption of electrical energy in air chillers by using little water by about 30%.

Chiller device

Scroll air cooled compression chillers

These systems are designed and produced from the capacity of 3 to 10 tons of cooling in the form of mini chillers and from the capacity of 12 to 100 tons of cooling in the form of chillers to supply the cold load of the building and industrial applications. Gases compatible with nature in the air-cooled condenser of the device are discharged to the environment outside the building, and there is no need to use a cooling tower and excessive water consumption. Therefore, air chillers have simple maintenance and operation conditions due to no need for a cooling tower and related accessories. In Safiad scroll air chillers, highly efficient brazed plate heat exchangers made of stainless steel (S.S.316) or shell and tube exchangers with carbon steel shells and copper tubes are used as evaporators. The chillers have control They can be programmed and adjusted, PCB or PLC.

Mini chillers are designed and produced in various models and in one and two separate circuits. According to the needs of the consumer, it is possible to use Hertic scroll compressors made by Danfoss or Koplid.